Elon Musk explains the repair concerns associated with the new body structure

Rich Benoit set up his YouTube channel to fix rescued Teslas. It was not difficult to find affordable electric cars that were affordable. Some had scratches in their battery packs, but insurance companies believed that replacing them was more expensive than paying for new cars. This explains why and when fears arose Tesla It decided to make the battery a structural part of its vehicles. OK, Elon Musk Take it up on Twitter.

Although he did not go into detail about how easy it would be to repair such a car, he did give his followers some general ideas of how this might work.

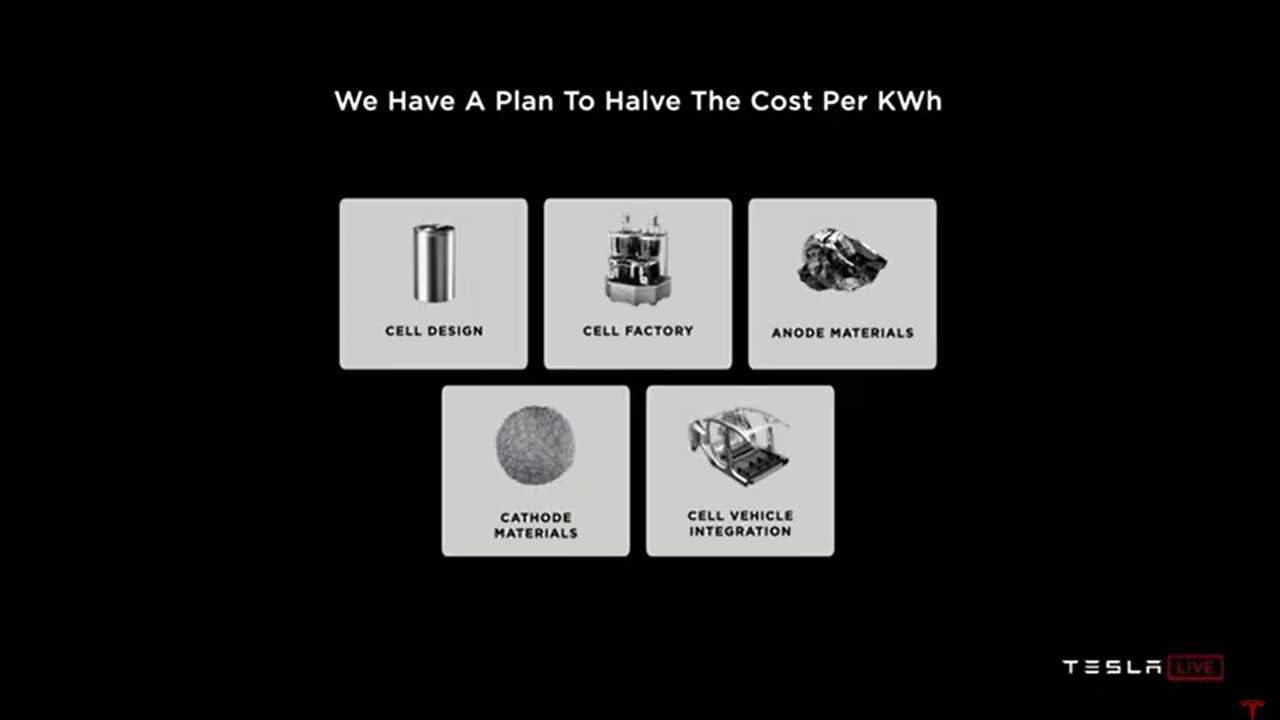

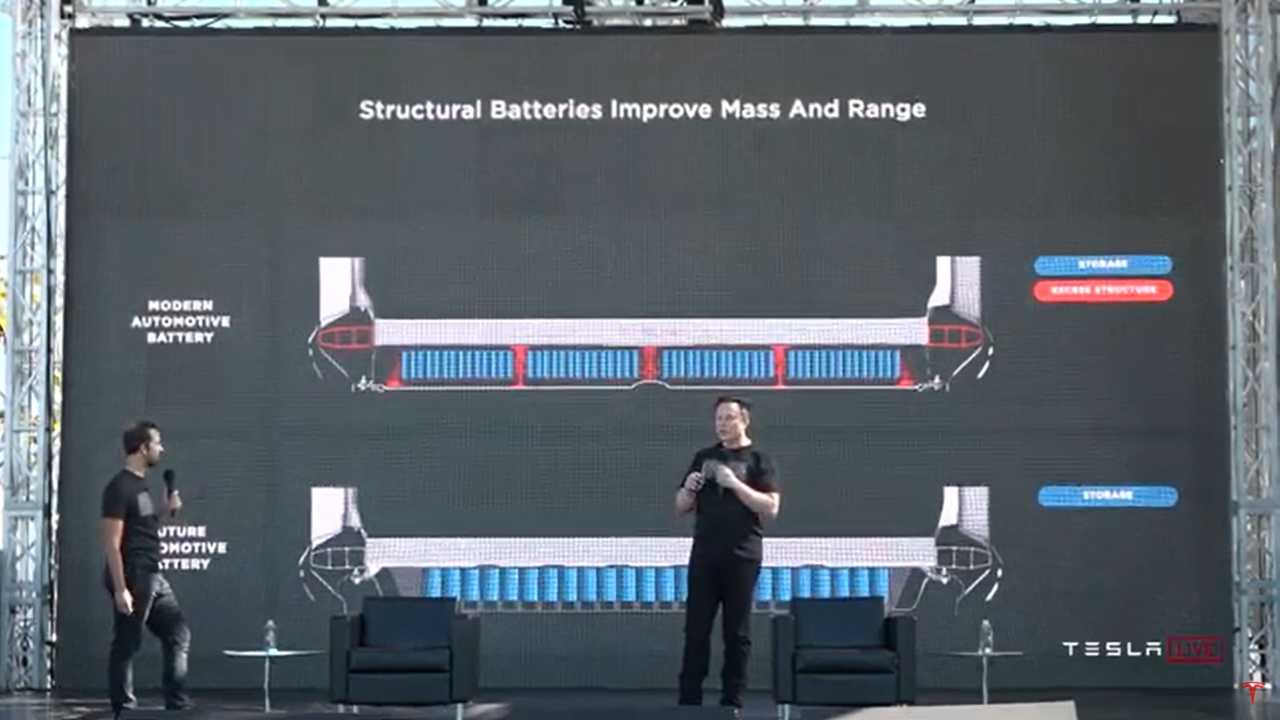

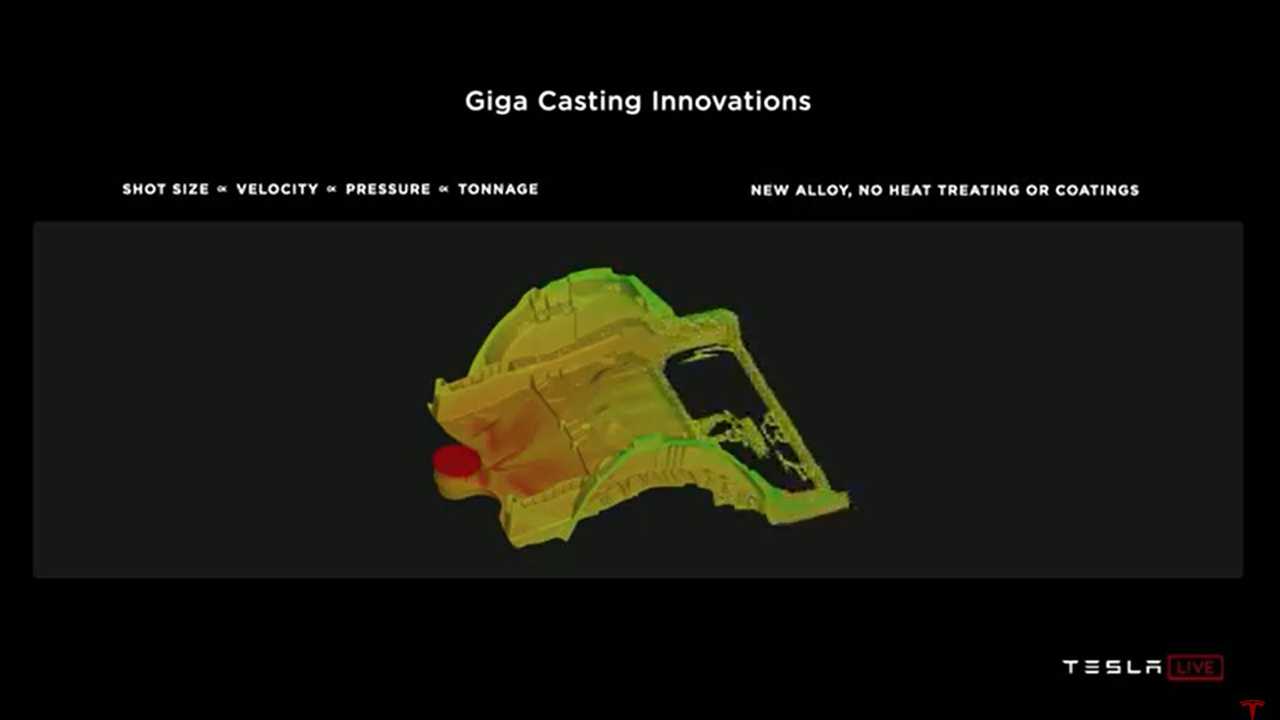

Elon Musk said if you weren’t aware of what we were talking about Tesla battery day That the company’s vehicles of the future will have an entirely new chassis. Instead of the usual white body structure we have nowadays, its platform would consist of three parts: two massive castings – one for the back and the other for the front – and a skeleton battery placed between them.

Although this might sound great at speeding up manufacturing, it also means that a breakdown affecting any of these parts will require replacement. If the battery pack presents any problems, how do you replace it if it is part of the bodywork?

Some followers asked Musk about it. Here’s his answer to a question about a rear-end collision.

Not everyone was happy with Musk’s solution.

Shortly before that, another follower asked him how the Skeleton Battery was made.

Some terms need clarification here. Stamps and castings are very different processes. Stamping turns an ordinary metal plate into a body plate by cutting and bending it under heavy pressure. Casting is made as a component of an automobile with a die filled with molten alloy.

Looking at the holder talking about the top and bottom steel plates, it is likely that the structure in which the battery pack will help be made of stamped parts. He did not say how many panels would be needed, but there is no way to seal this large panel in one piece. It will not be rigid enough.

When Musk said the battery pack would provide “shear transmission,” he followed suit with building terminology. Shear walls provide lateral strength and rigidity to buildings. If you think of a structural battery pack this way, a bonded battery pack will likely work like this one. Check out the video below to understand it better.

To make it simpler, shear forces come from road loads, such as bumps, acceleration, rotation, etc. These forces are fed to the wheels, then from the wheels to the suspension, from the suspension to the chassis, etc. It should spread through the car efficiently to give it the feeling of being solid.

Imagine a shoebox with thin walls. If you press one of its sides, it will easily bend there. If it is wooden box or other more solid object, it will be fully paid. This happens because the force placed there is evenly transferred to all of its structures.

Oddly enough, Musk’s words give us the idea that the battery pack and steel face panels are independent, even if they’re connected in some way. How are they squeezed between them to form the central body of the car? If the battery pack is just a component between these steel plates, does that mean you can replace these panels and keep the battery pack?

If that is the case, we might see fewer Tesla write-offs due to damage out there. At the same time, how would the battery pack be structural if this were the case?

InsideEVs They spoke to engineers who would prefer to remain anonymous, and said they had other concerns. Will these batteries withstand these shear forces and still be able to operate without structural damage? How strong do they need to be to ensure both jobs?

They are also concerned about Musk’s reform strategy. If a meltdown affected massive castings, it might technically be possible to replace them, but would that make financial sense? Or will it cost more than just paying for a brand new car? That could lead to higher insurance rates for Tesla cars – and they’re not really cheap.

On the other hand, the same engineers believe that if Tesla can make this arrangement work – in terms of serviceability and weight reduction – that would be a very elegant solution. The German Y might tell us more about that.

Aside from the engineering questions involved, there is also an environmental aspect to consider. If these cars were written off after minor accidents, it would make the junk yard much more crowded than it is today. We’ll need a platoon of Rich Benoit to fix it to avoid waste and the need for more natural resources to build new ones. Unfortunately, even the man himself had already given up on doing this.

“Explorer. Devoted travel specialist. Web expert. Organizer. Social media geek. Coffee enthusiast. Extreme troublemaker. Food trailblazer. Total bacon buff.”